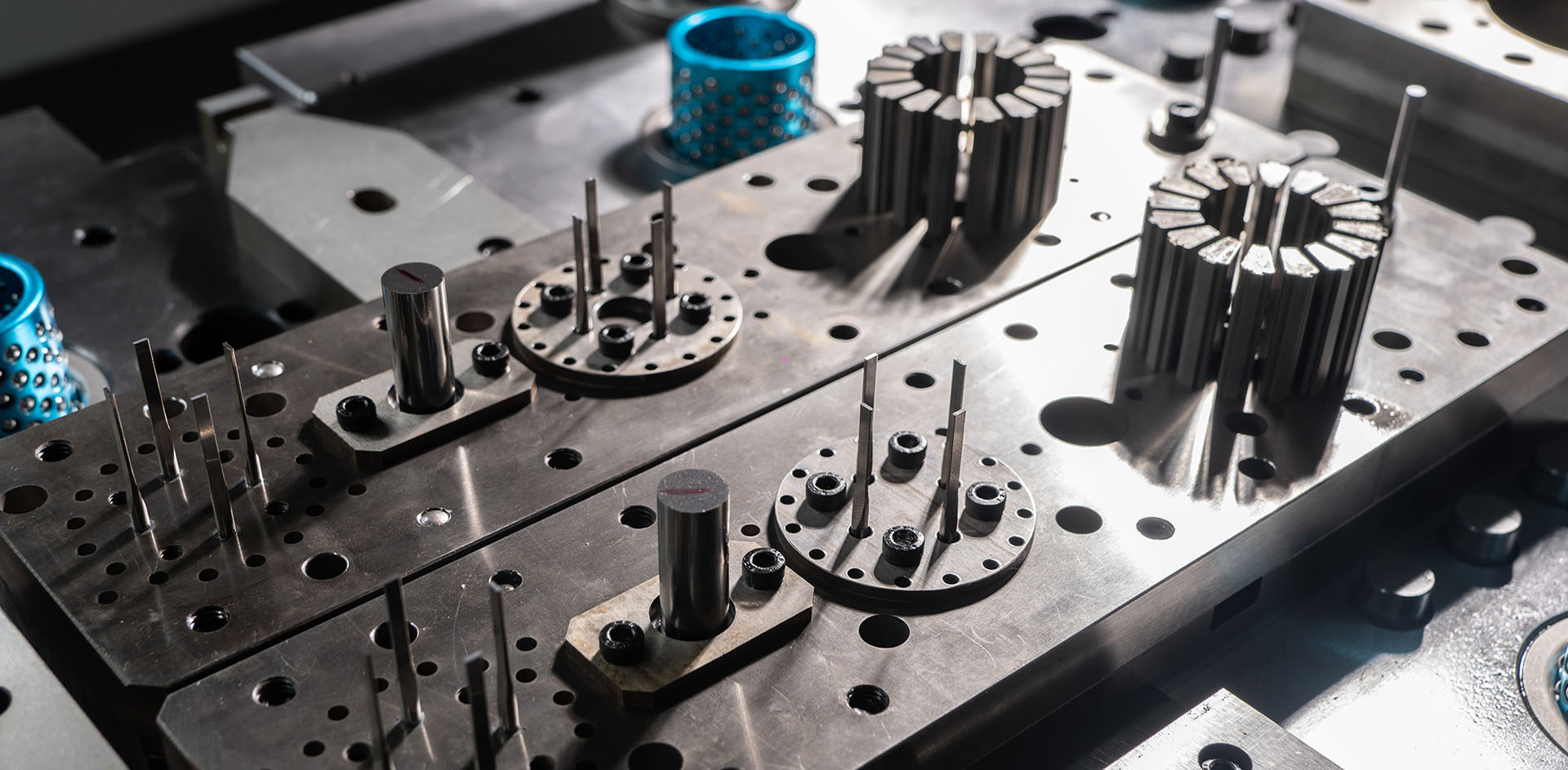

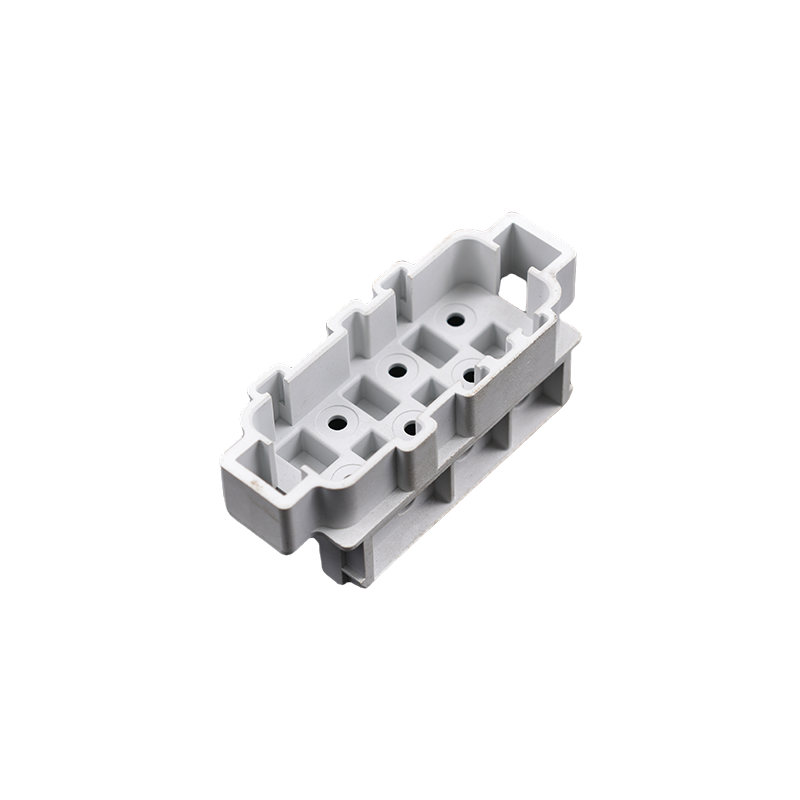

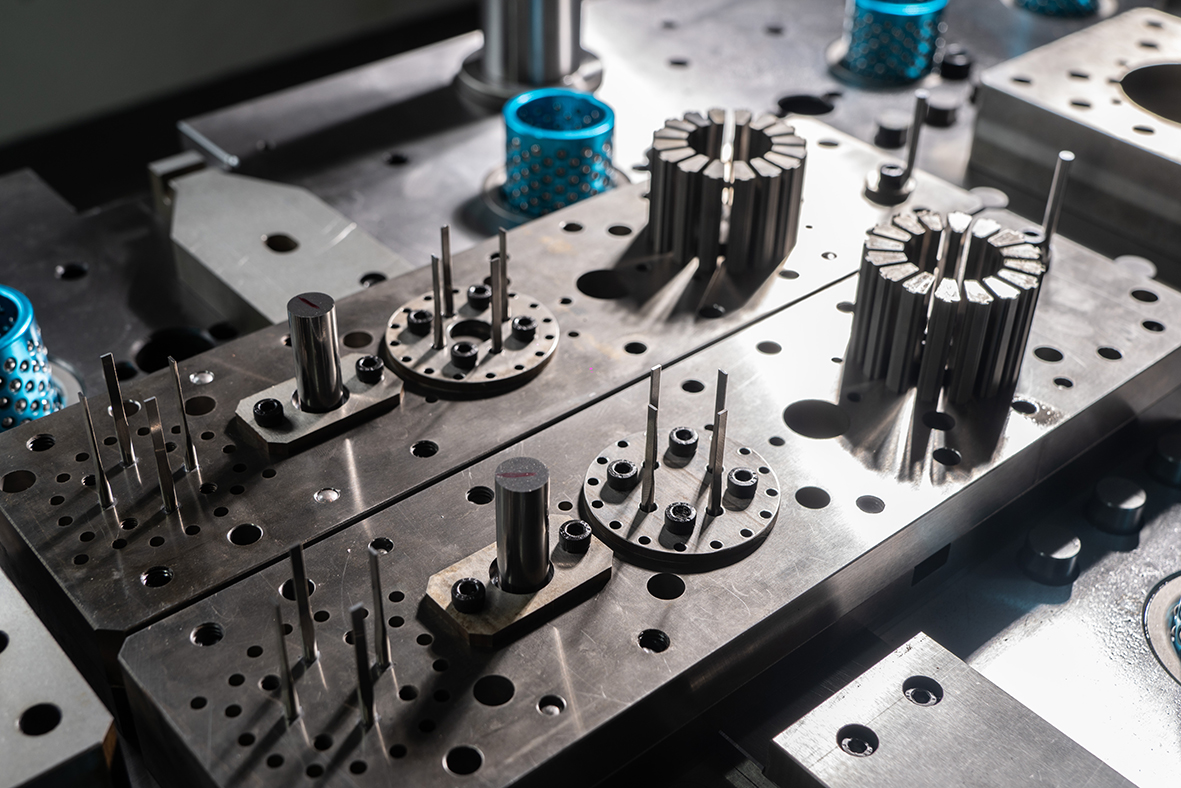

Precision Motor Core Die

The automatic lamination iron core dies adopt a multi-station progressive method. The die is equipped with cylinders, laminating punches, press-through punches, press-in punches, shaping rings and other components. The required number of stacking laminating pieces is set through the punching machine control panel, and a signal is given to the solenoid valve. Then the solenoid valve drives the cylinder to run. The cylinder controls the depth of the riveting punch and the punch punch to achieve the effect of riveting and splitting, thereby stacking and riveting iron cores of different thicknesses. Classificcation: As per motor type: shaded pole motor, series motor, induction motor, generator, stepper motor, brushless motor, servo motor, compressor;As per the mold form: two-plate, three-plate, inner and outer guide column, single row, double row, three rows and four rows, inner rotor skew slot, outer rotor skew slot, loose sheet, stack riveting, special-shaped segmented stack riveting, 180 large rotation, etc.;As per the material type: 0.10mm oriented silicon steel loose sheet, 0.20mm non-oriented silicon steel stack riveting mold, 0.30mm oriented silicon steel stack riveting mold, 0.35mm non-oriented silicon steel stack riveting mold, 0.5mm silicon steel/cold rolled plate stack riveting mold, 0.65mm non-oriented silicon steel stack riveting, 0.80mm cold rolled plate stack riveting mold, 1.00mm cold rolled plate/galvanized plate stack riveting mold.

View More

Language

Language  简体中文

简体中文