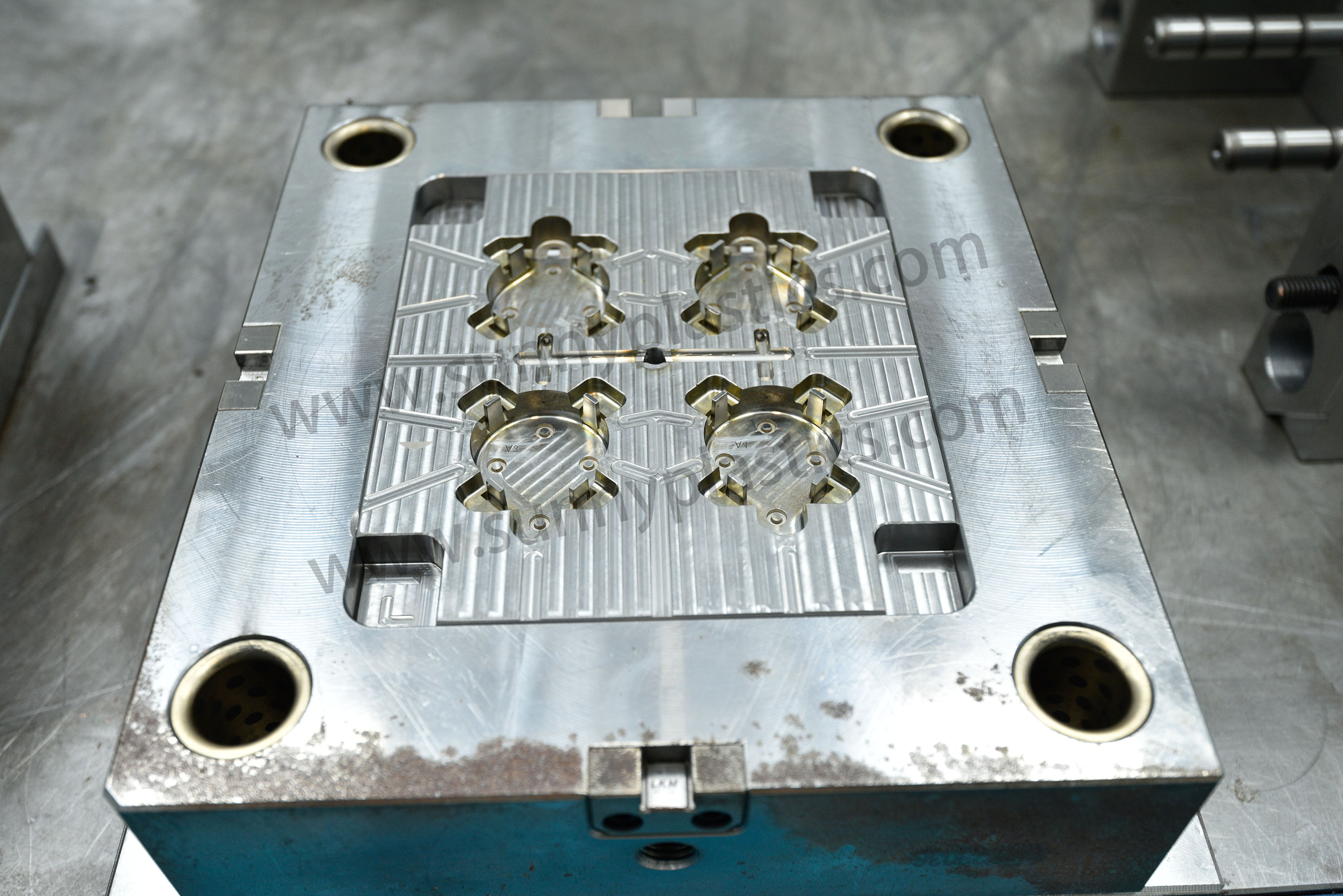

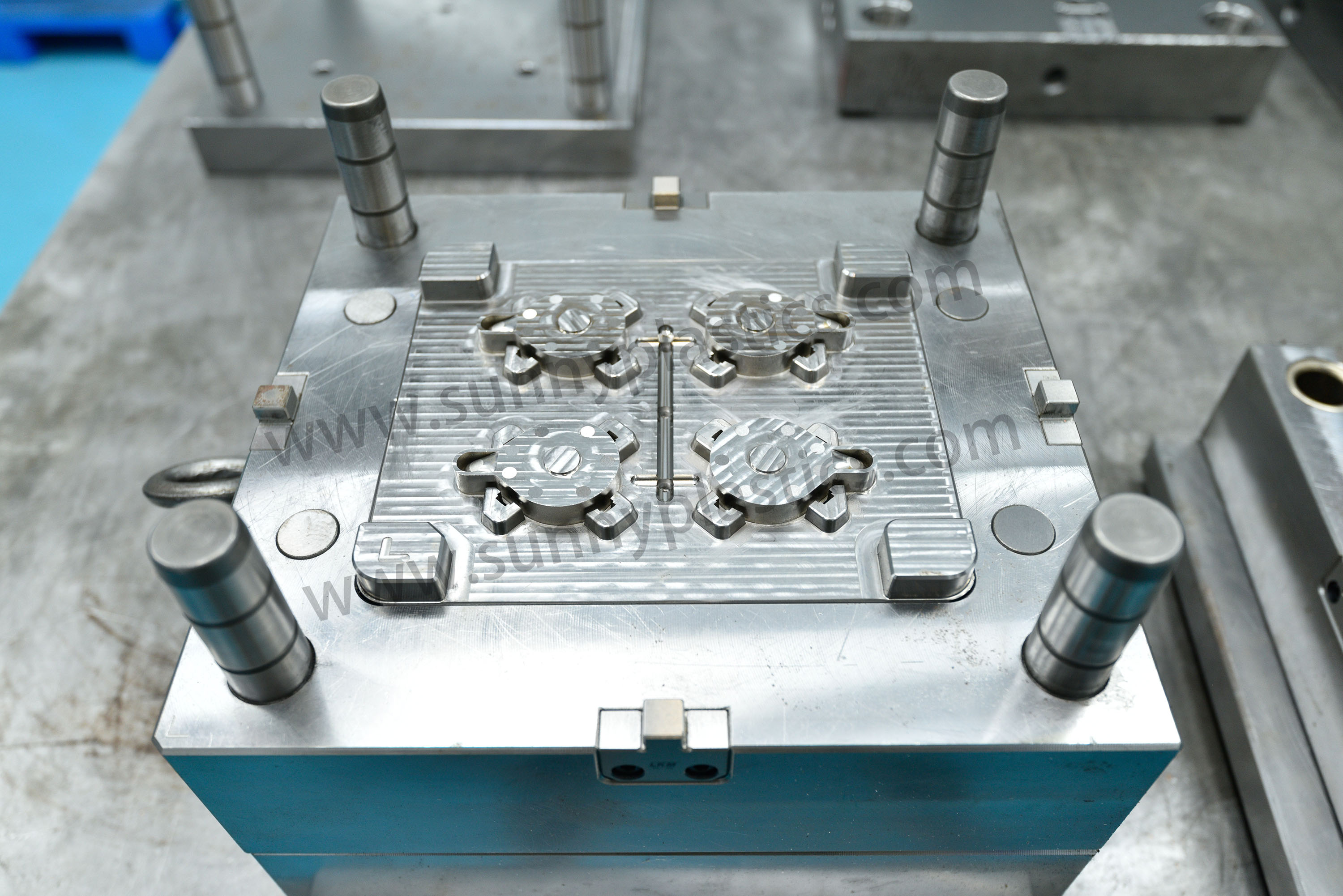

Precision mold/tool making for injection molding is part of SUNNY PLASTICS TECHNOLOGY's vertically integrated offering, which means you benefit from our extensive knowledge and understanding of the production and assembly process.

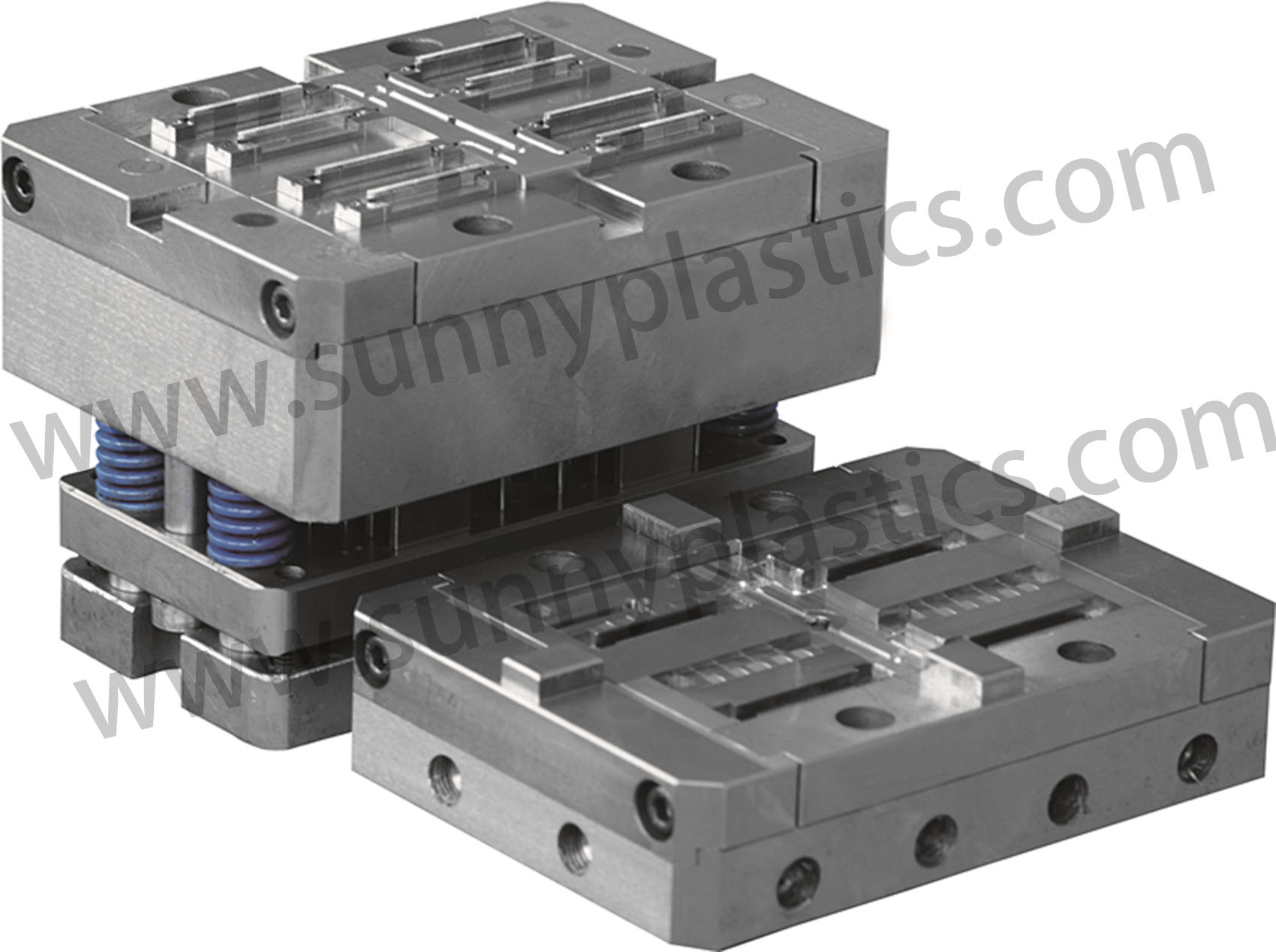

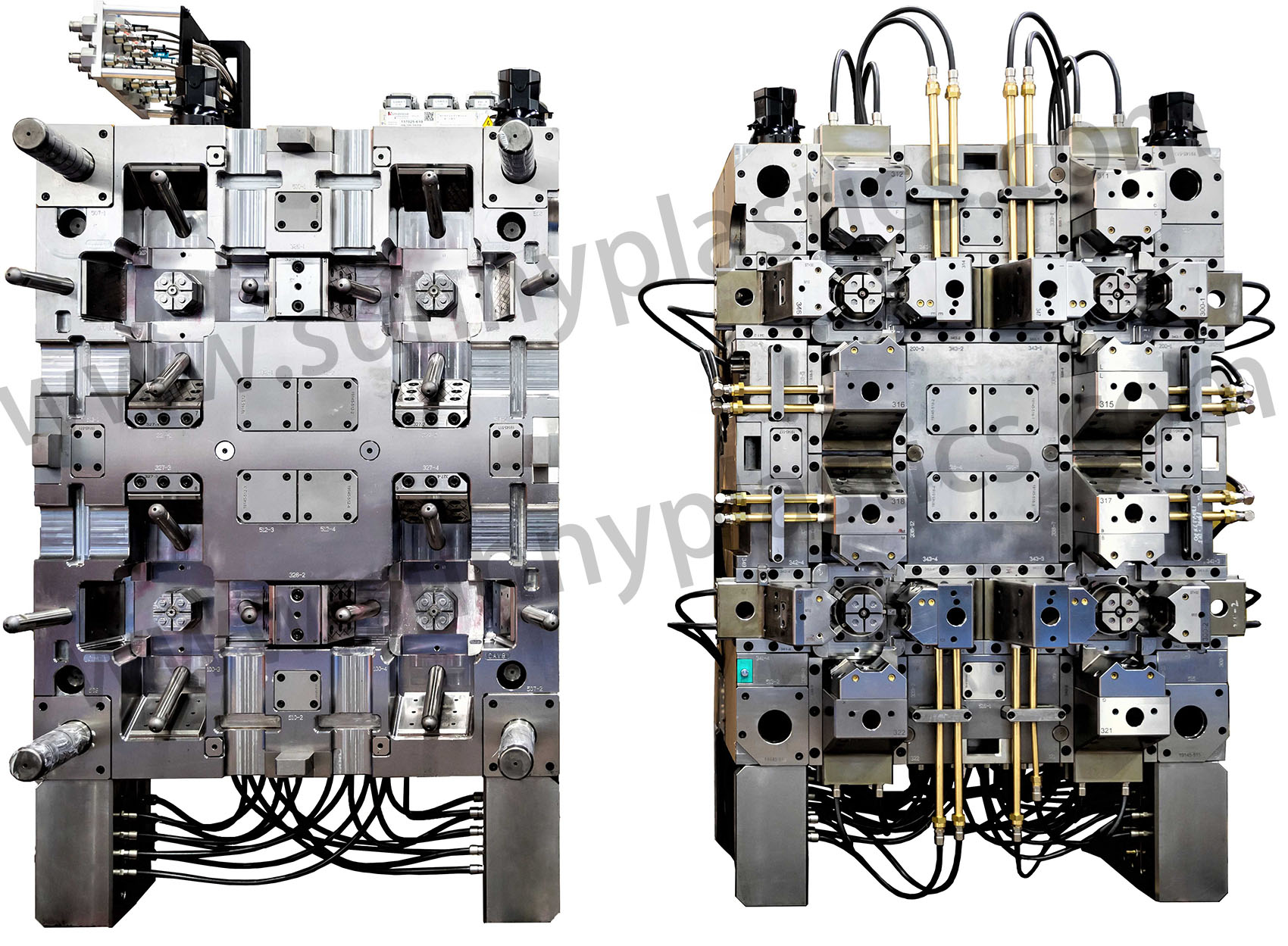

SUNNY PLASTICS mold capabilities

SUNNY PLASTICS has experienced injection molding precision mold/tool making engineers and machinists from around the world who can work with you in your tool making process to help you:

>Design for Manufacturability (DFM)

>Verify tolerances

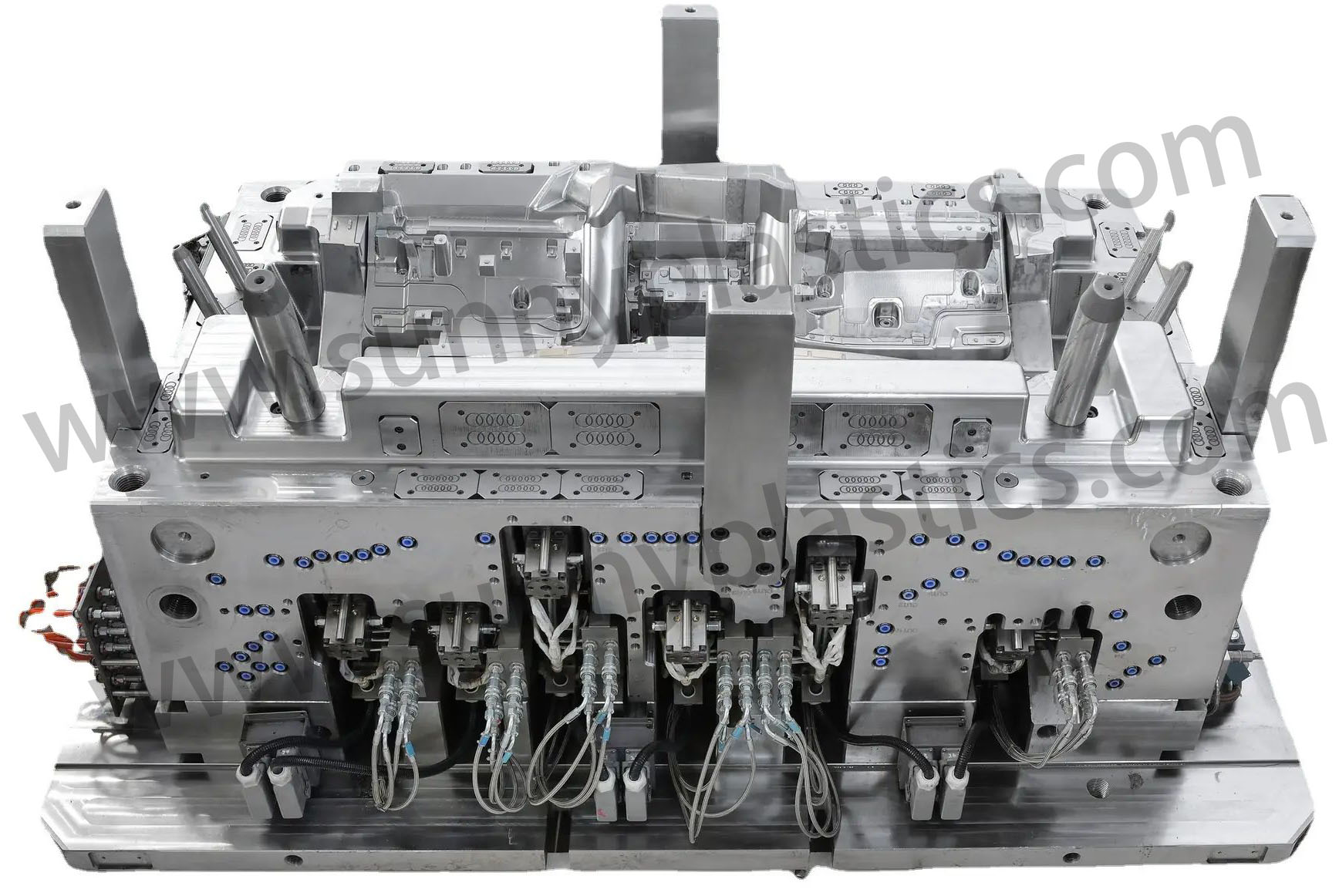

>Cooling system options & gate locations and options

>Hot runner options and cost effectiveness

>Potential traffic issues

>Tool material/steel selection

>Final Tooling Design Review

How we can help

We fully understand the impact that tolerance management has on your product assembly process and ensure that the service we provide is of the highest standard.

Ability to validate tools in-house using our 3D CMM.

Internal tool design

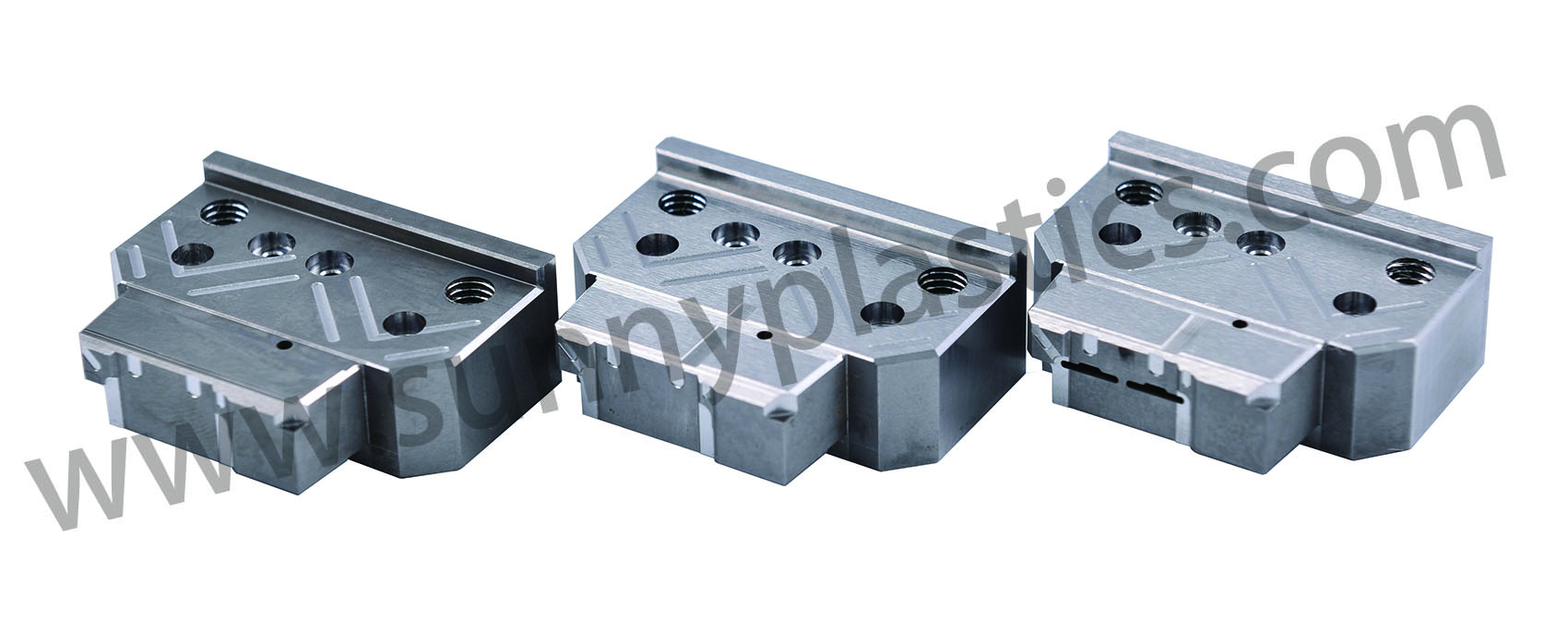

Our plastic injection tool manufacturing engineers have a complete checklist that they use for every tool design and tool manufacturing. We are able to make P20 or H13 steel tools at 1/3 to 1/2 the cost of other countries' aluminum tools.

Therefore, in order to better serve our customers and provide better products, we started producing steel tools exclusively around the world. With a more efficient system, we can make steel tools in the same time as aluminum tools while delivering a better finished product at a lower cost.

Advantages of Injection Tool Services for Product Developers

Our Advantages:

Optimize customer product design and reduce assembly processes without affecting customer functionality.

Optimize products and reduce manufacturing costs (material costs, time costs).

Analyze product issues and provide solutions.

Injection molding machines: 80 units of 20T-400T, capable of meeting various production requirements.

The qualification rate of T1 is over 90%.

More than 80 precision CNC machining centers ensure high output and precision.

We have the world's advanced German HERMLE C22, C42, and C62 five axis CNC machining centers, with a workpiece weight of up to 2500 kilograms, capable of producing top-notch turning and milling products.

Over 20 years of rich industry experience.

Having a strong engineering design and project team.

Various complete surface treatment processes fully meet the requirements of product appearance and surface performance.

Language

Language  简体中文

简体中文

Product Pictures

Product Pictures