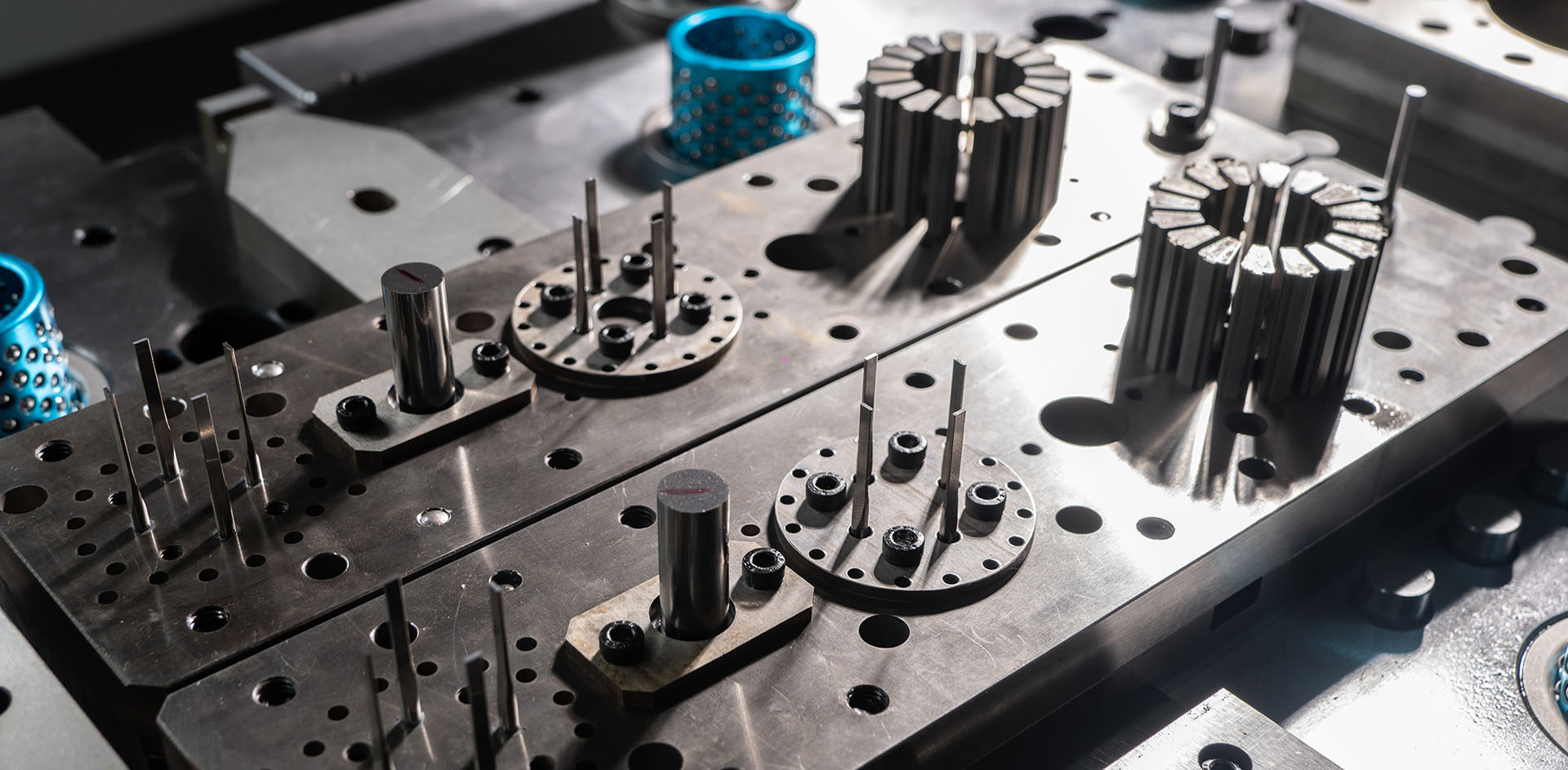

With the rapid advancement of digital technologies, the precision mold industry is undergoing an unprecedented transformation. The application of digital manufacturing technologies has significantly enhanced production flexibility and effectively reduced production costs, providing mold manufacturers with a marked competitive advantage.

Firstly, digital manufacturing integrates Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) systems, achieving seamless integration between design and manufacturing. Designers can use advanced CAD software to precisely design molds, while CAM systems automatically generate machining paths, ensuring the precise manufacture of molds. This highly integrated process reduces human errors, improves production efficiency, and also shortens the time from design to market for products.

Secondly, digital manufacturing technologies such as 3D printing and additive manufacturing offer new possibilities for mold making. These technologies can quickly produce mold components with complex shapes, reducing the time and cost required by traditional machining methods. Additionally, 3D printing technology enables rapid prototyping of molds, making design verification and modification faster and more flexible.

Furthermore, digital manufacturing introduces intelligent manufacturing systems, such as the Internet of Things (IoT) and big data analysis, to achieve real-time monitoring and optimization of the production process. These systems collect production data, analyze production efficiency and quality issues, helping manufacturers to adjust production strategies in a timely manner, reduce resource waste, and lower production costs.

Moreover, digital manufacturing also facilitates the optimization of the supply chain. Through digital platforms, mold manufacturers can communicate with suppliers and customers in real-time, quickly respond to market changes, and enhance the flexibility and responsiveness of the supply chain. This efficient supply chain management helps reduce inventory costs and improve overall operational efficiency.

In conclusion, the application of digital manufacturing technologies is fundamentally changing the landscape of the precision mold industry. It not only enhances production flexibility, enabling mold manufacturers to respond more quickly to market changes, but also reduces production costs through the optimization of production processes and supply chain management. As technology continues to evolve, digital manufacturing will continue to drive the mold industry towards greater efficiency and intelligence, offering more innovation and growth opportunities for the sector.

Language

Language  简体中文

简体中文