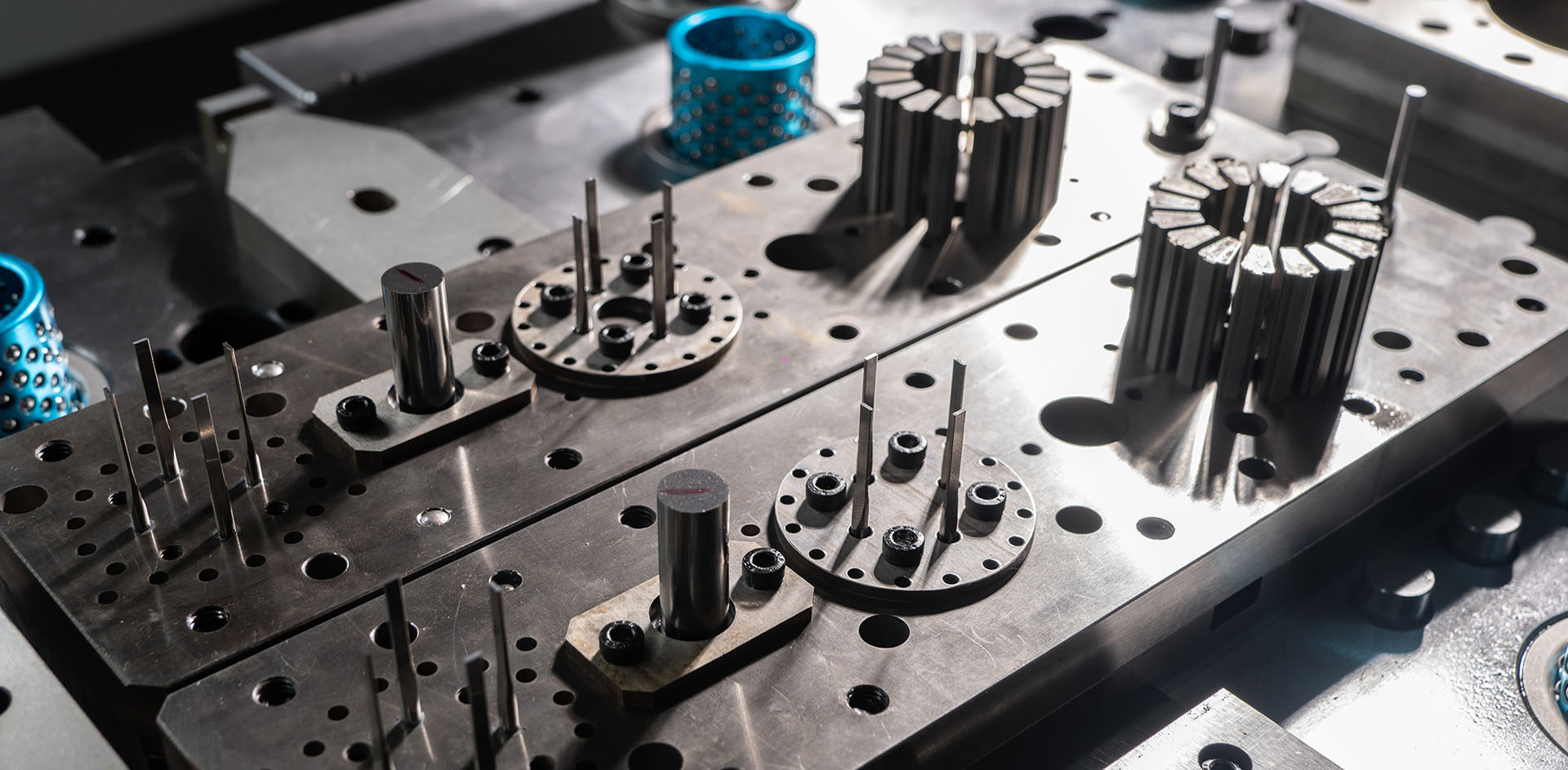

In the manufacturing industry, precision molds are critical tools for producing high-quality products. However, wear and damage to molds can lead to production disruptions, increased costs, and compromised product quality. Therefore, implementing effective mold maintenance strategies is crucial, as they not only extend the lifespan of molds but also reduce interruptions during production.

Firstly, preventive maintenance forms the foundation for extending the life of molds. This includes regular inspections for wear, cleaning the mold surfaces, and lubricating moving parts. By conducting regular maintenance, potential issues can be identified and addressed promptly, preventing minor problems from escalating into major failures.

Secondly, using high-quality materials and advanced manufacturing techniques to create molds can enhance their durability. Selecting abrasion-resistant and corrosion-resistant materials, along with employing precise machining technologies, ensures that molds maintain optimal performance over extended use.

Additionally, establishing a detailed mold maintenance record system is essential. Recording the date of each maintenance, the content of the maintenance, and the usage of the mold helps track performance changes and predict potential issues. This data-driven maintenance strategy enables businesses to plan maintenance activities more effectively and avoid unnecessary production disruptions.

During the mold usage process, operator training is also of paramount importance. Ensuring operators understand the correct usage and maintenance procedures for molds can reduce damage caused by improper operation. Furthermore, operators should undergo regular training to stay abreast of the latest maintenance technologies and best practices.

Lastly, adopting advanced monitoring technologies, such as sensors and data analysis software, can provide real-time monitoring of the mold's working condition. These technologies offer instant data on mold performance, enabling the maintenance team to detect and resolve issues promptly, thereby reducing the risk of production interruptions.

In conclusion, precision mold maintenance strategies are vital for ensuring production efficiency and product quality. By implementing preventive maintenance, using high-quality materials, establishing maintenance record systems, training operators, and adopting advanced monitoring technologies, businesses can effectively extend the lifespan of molds, minimize production disruptions, and enhance overall production efficiency and competitiveness. As technology continues to evolve, these maintenance strategies will continue to develop to meet the manufacturing industry's growing demand for efficient and reliable molds.

Language

Language  简体中文

简体中文